If you’ve ever wondered how robots move with such precision, or how remote-controlled cars can steer so accurately, chances are you’re looking at servo motors in action. These remarkable devices are everywhere in our modern world, yet many people don’t fully understand what they are or how they work.

What Exactly is a Servo Motor?

Think of a servo motor as a regular electric motor with a built-in brain. While a standard motor just spins continuously when you apply power, a servo motor can rotate to a specific angle and hold that position with incredible accuracy. It’s like the difference between a spinning wheel and a precise robotic arm that can point exactly where you tell it to.

The word “servo” comes from the Latin word “servus,” meaning servant. That’s essentially what these motors do – they serve your commands by moving to exact positions and staying there until you tell them otherwise.

The Anatomy of a Servo Motor

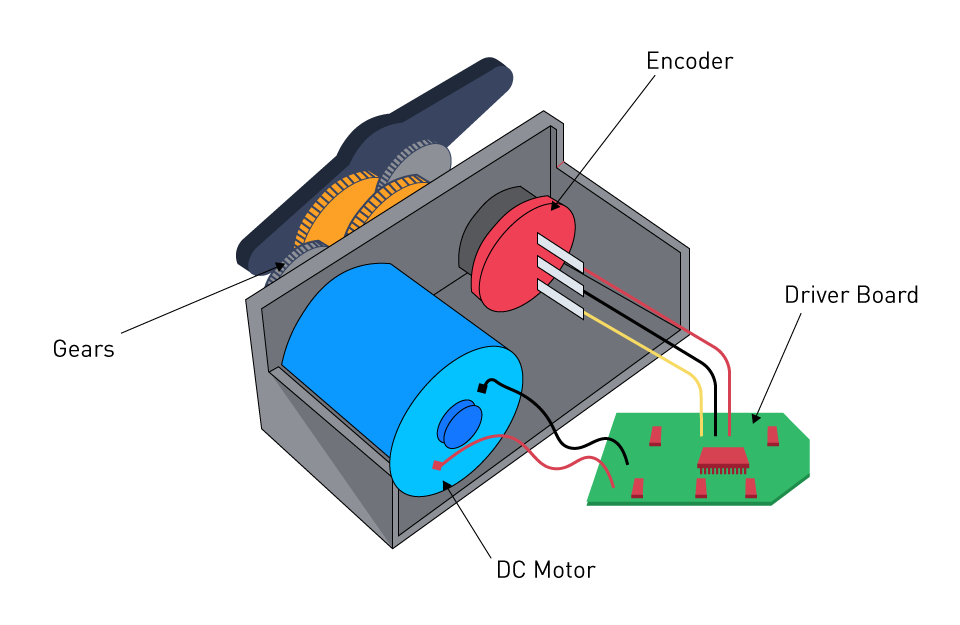

Every servo motor contains three main components working together:

The DC Motor provides the actual movement and power. This is the muscle of the system.

The Control Circuit acts as the brain, processing your commands and determining how much the motor needs to move.

The Feedback System serves as the eyes and ears, constantly monitoring the motor’s current position using a potentiometer or encoder.

These three components work together in what engineers call a “closed-loop system.” The motor moves, the feedback system reports the current position, and the control circuit makes adjustments to reach the exact target position.

How Do Servo Motors Actually Work?

Imagine you’re trying to park your car in a tight space. You turn the wheel, check your position, adjust, check again, and repeat until you’re perfectly positioned. Servo motors work similarly, but they do this hundreds of times per second.

Here’s the process:

- You send a control signal telling the servo where to go

- The control circuit compares this target with the current position

- If there’s a difference, the motor starts moving in the right direction

- The feedback system continuously reports the current position

- When the motor reaches the target, it stops and holds that position

This entire process happens so quickly that the movement appears smooth and precise to our eyes.

Types of Servo Motors You’ll Encounter

Standard Servos are the most common type, typically rotating about 180 degrees. These are perfect for applications like steering mechanisms or camera mounts.

Continuous Rotation Servos can spin full circles like regular motors, but you can control their speed and direction precisely. Think of them as regular motors with better manners.

Linear Servos move in straight lines instead of rotating, perfect for applications like automatic door locks or precise positioning systems.

Where You’ll Find Servo Motors

Servo motors are surprisingly common in everyday life:

Remote-Controlled Toys use tiny servos for steering cars, moving robot arms, and controlling airplane flaps.

Industrial Automation relies heavily on servo motors for assembly lines, packaging machines, and robotic manufacturing.

Automotive Systems use servos for power steering, throttle control, and various adjustment mechanisms.

Home Appliances incorporate servos in everything from washing machine door locks to automatic pet feeders.

Medical Equipment depends on servo precision for surgical robots, MRI machines, and patient positioning systems.

Why Choose Servo Motors?

The main advantage of servo motors is their precision. While a regular motor might be accurate to within several degrees, a good servo motor can position itself to within fractions of a degree. This precision comes with excellent holding power – once positioned, a servo motor will maintain its position even against external forces.

Servo motors also offer excellent speed control and can accelerate or decelerate smoothly, making them ideal for applications requiring gentle, precise movements.

Getting Started with Servo Motors

If you’re interested in experimenting with servo motors, they’re surprisingly accessible for beginners. Small hobby servos cost just a few dollars and can be controlled with simple microcontrollers like Arduino or Raspberry Pi.

Most servo motors use a standard three-wire connection: power, ground, and control signal. The control signal is typically a PWM (Pulse Width Modulation) signal that tells the servo where to position itself.

Common Applications for Beginners

Robotic Arms are popular first projects, allowing you to create a simple pick-and-place mechanism.

Camera Tracking Systems can automatically follow subjects or create smooth panning effects.

Automated Blinds or Curtains provide a practical home automation project.

Pet Feeders can dispense food at scheduled times with precise portion control.

Things to Keep in Mind

When working with servo motors, remember that they consume power continuously while holding position. This is different from stepper motors, which only use power when moving.

Also, servo motors work best within their specified range of motion. Trying to force them beyond their limits can damage the internal feedback mechanism.

The Future of Servo Motors

As technology advances, servo motors are becoming smarter and more efficient. Modern servos can communicate digitally, provide detailed status information, and even adapt their performance based on the load they’re carrying.

Whether you’re building your first robot or just curious about the technology around you, understanding servo motors opens up a world of possibilities for precise, controlled movement in countless applications.

Ready to Get Started?

Servo motors represent one of the most accessible entry points into precision motion control. With their combination of accuracy, reliability, and ease of use, they’re perfect for both learning and practical applications. The next time you see something moving with remarkable precision, there’s a good chance a servo motor is making it happen.